Entering and processing a Service Order without Call Activities

Creating a service order

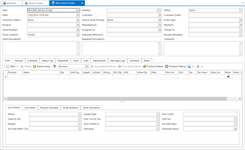

- Log onto Readysell>Service>Service Orders.

- Click New to create a new service order. (If you want to use a template, see Service Order Templates.)

The Service Order detail window will display.

- Enter details for the service order:

- Select the Customer that the work is getting done for. (if you have a machine linked to a customer you can select the correct machine id from the drop down in the machine field)

- Machine: Select the machine to be serviced. (If you select the machine first of, the customer linked to the machine will populate to screen.)

The address has to be flagged as 'Physcial' on the customer's account.

The physical address on the machine will be the address that is on the service order/template. - Product: Select the product to be serviced. (if you have selected the machine first off, the product linked to the machine will populate to screen)

- Customer order - insert the customer order reference for this service work

- Priority - you may wish to select a priority or leave the default

- Order Type = you may wish to change the order type or leave the default

- Charge to - you may wish to charge another customer for this work, if so select the correct charge to otherwise leave the default cardid in the chargeto

- Work Location - you can leave the default or make a selection from the drop down list.

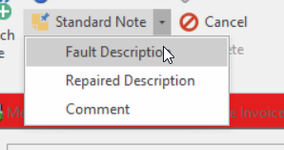

Fault Description - You can select a fault description from the action button in the top tool bar 'Standard Note' to best suit the fault and/or you can type in a description or add to the standard note fault.

- Assigned To: When you insert a machine or customer at the start, the assigned to field may auto fill in with a Technician as the technician may already be assigned to this machine. You may wish to select a different technician for this job.

Once you have finished filling in all the header details and fault description for this machine, click Save. The service order is now ready to be worked on.

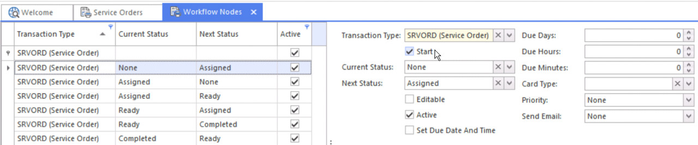

You can now change the workflow status on the service order from NONE to Assigned or whatever status you require the service order to be next.The workflow status can be changed at this point by anyone that has worked on or looked at the service order and product. Any changes to the service order's status are recorded in the audit trail on the Status Log tab.

As work is performed on a service order, technicians record their work and travel time as activities on that service order. Activities are shown in the service order's Activities tab if you wish to use this feature or just enter the products on the lines of the service order.

It is best practice to maintain your workflow status before you commence inserting call activities.

If a machine doesn't have a technician assigned to it, it is not until you assign a technician to a service order or update the workflow status that a service call activity log is generated

A service order can have many service call activities as a technician may get another call out.

If you wish to use Service Call Activities to track the technicians call outs and work refer to the link Entering and Processing a Service order with call activities

Finishing a Service Order

The service order can be shipped, invoiced or completed once the service request is complete and the Workflow Status is set to the required stage e.g., Ready.

If you wish to add more lines to the service order lines, change the workflow status back to Assigned, add your lines and then change the workflow status to Ready.

Once the status on the service order is set to Ready, the Ship and Complete action buttons become visible.

The required Workflow Nodes need to be set-up to facilitate the Workflow Status progression to the next stage e.g. None <=> Assigned <=> Ready <=> Completed

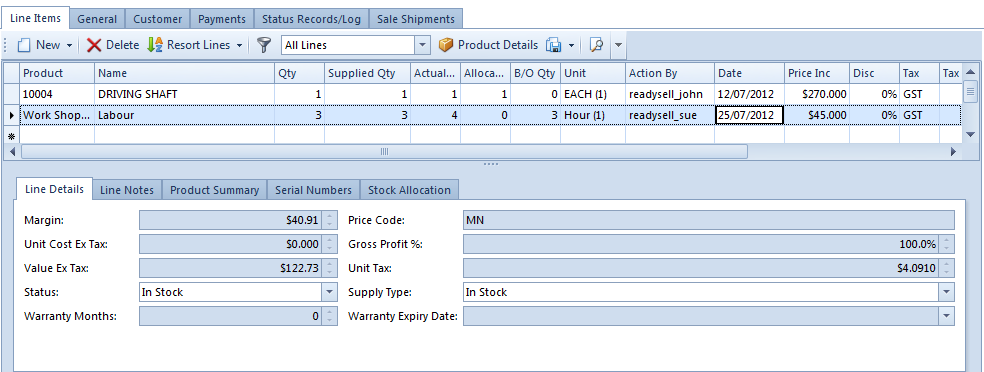

The line items on the Lines tab are used to invoice the service order. The value of a line item is determined by its product code. Products that stand for labour time have a sell unit based on time (e.g. "Hour") while parts have sell units based on quantity (e.g. "Each"). For labour products you can enter the actual hours used as well as the hours charged out. The labour profitability reports consider charged vs actual labour charges to work out how much time is being wasted when working on service orders.

The example below shows two line items. The first line item is the part used to repair a machine, and the second is the labour charge.