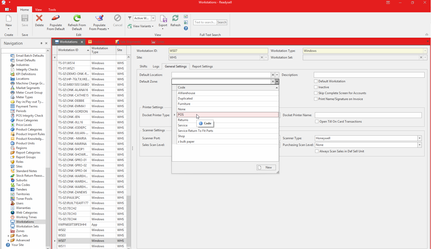

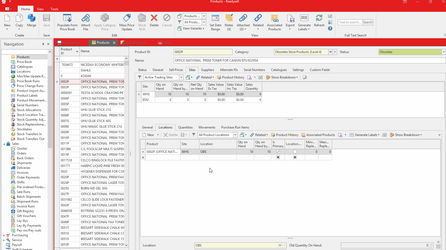

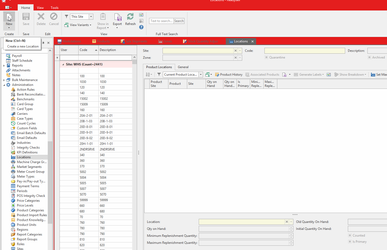

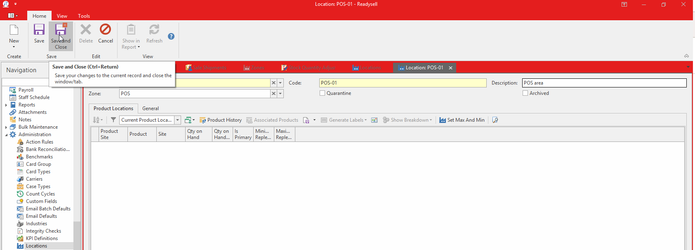

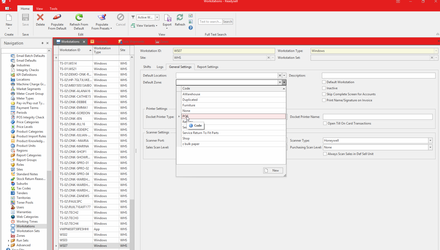

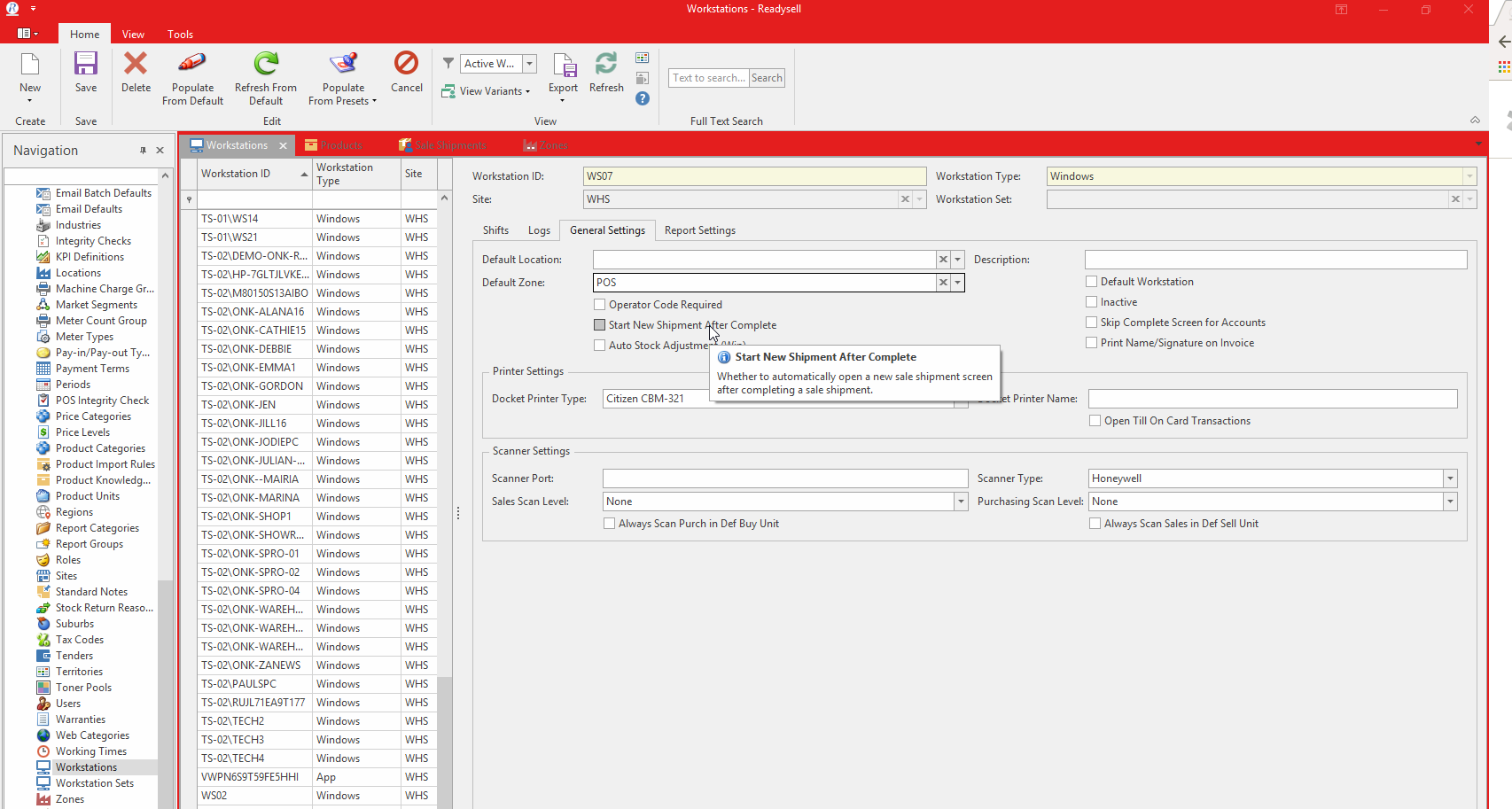

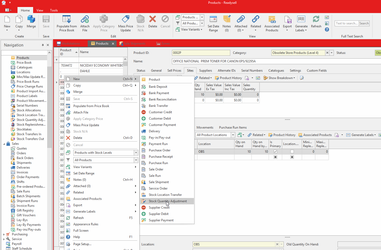

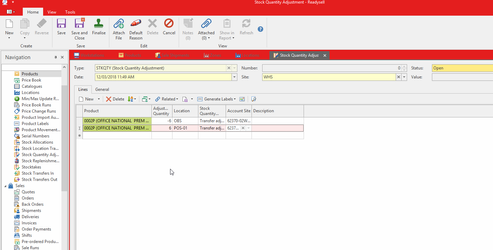

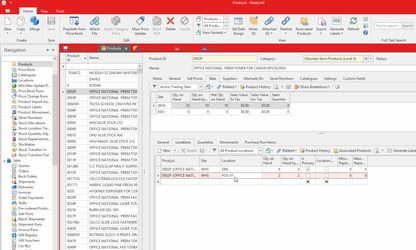

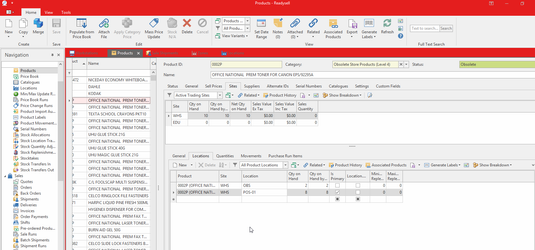

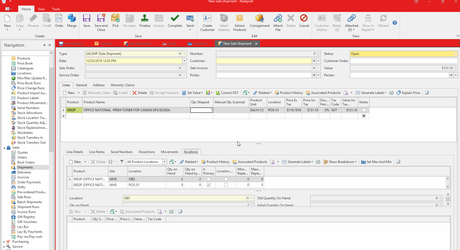

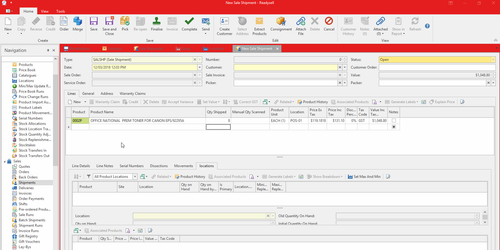

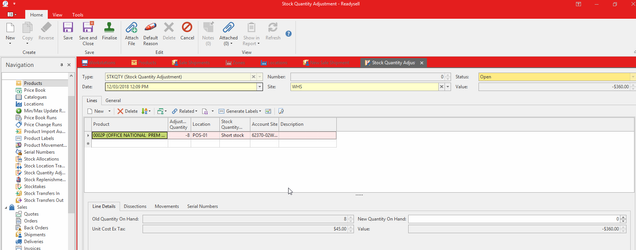

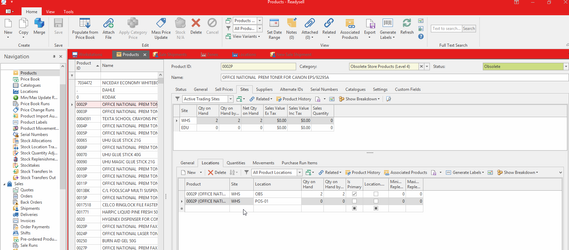

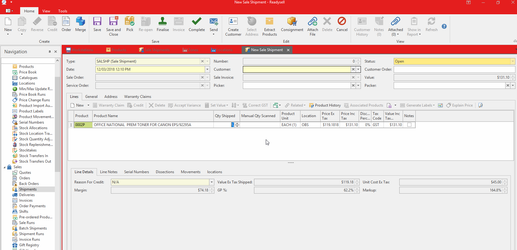

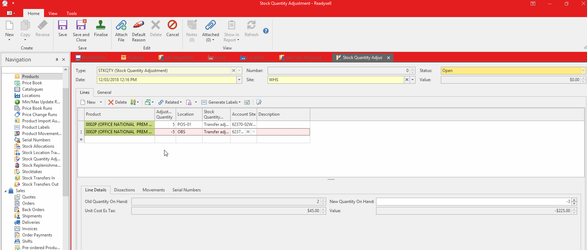

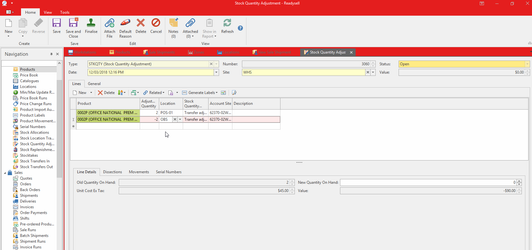

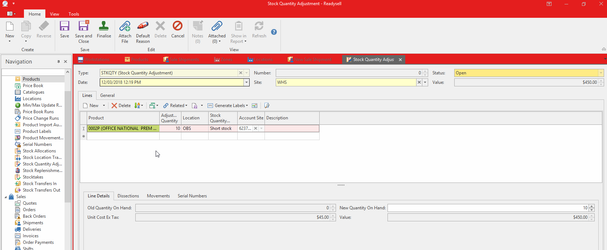

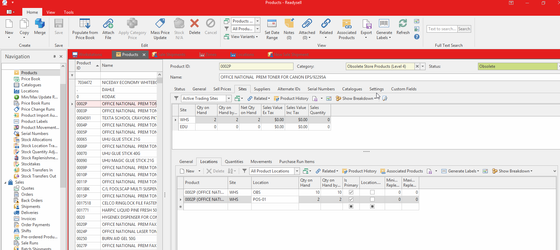

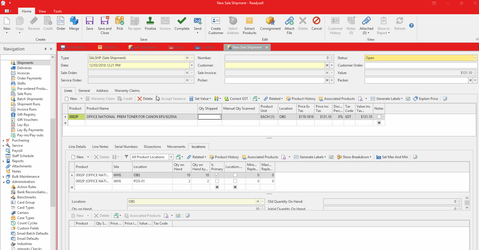

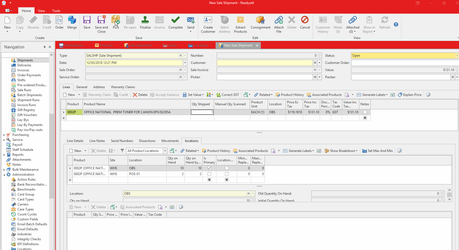

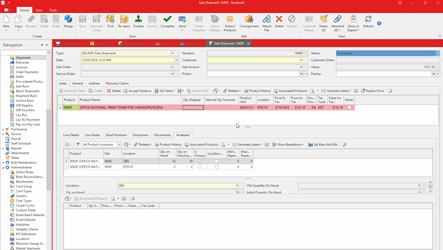

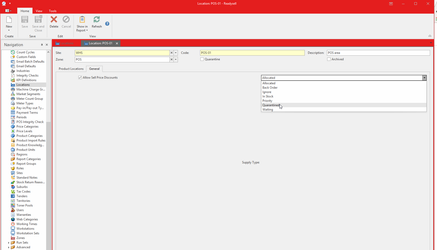

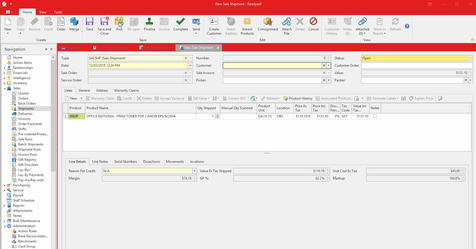

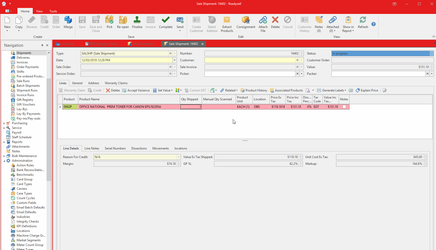

Workstations can have a default zone specified. The default zone can be used to make sale shipment lines entered from workstations in the POS area of the business put locations from the POS zone onto sale shipments. Preventing POS sale shipments from automatically selecting stock out of the warehouse. It is important to recognise the workstation default zone does not effect stock allocation and does not effect the "Pick" button or the "Pick" process when it is run by automatic warehousing. A retail area in the business which is/could have all it's location in a zone say "retail". All other workstations, other than POS workstations, would normally have the default zone remaining blank. If the user clicks the "Pick" button, when typing a sale shipment in from any workstation, including the workstations in the "POS" zone. All the rules above are ignored. As those special rules only apply to sale shipment lines that are typed into a sale shipment from a workstation that has a default zone specified. Those rules do not replace or change the default logic behind the "PICK" process. So if you press the "Pick" button, or if a sale order is entered from those workstations. The "Pick" process will set locations on the sale shipment lines considering all locations in the business. You do not need to put the warehouse workstations into any special zone You do have to ensure the POS operators do not press the "Pick" button when they enter sale shipments. I am on workstation 7. I want to assign a zone for POS. So I create a zone and name it POS by selecting administration, zones from the Navigation panel. Then clicking the "New" button to create a new zone. I then put my workstation 7 into the default zone of "POS" Then I selected a product, it could be any product that you wantt to stock in the warehouse and seperately stock in the retail zone. In this case I picked product "002P". Theproduct which only has stock in the warehouse. So I have to create a new location for the product in the pos zone. I created a location, it could have any name, but for the sake of this exersize, I named the new location in the pos zone "POS-01", put that location in the "POS" zone I created a new location for the product, move some of the stock from the warehouse location to the pos location. I used a stock adjustment to move stock from the warehouse to the new pos location. I could have also used a stock location transfer to do the same thing. I would use the stock location transfer approach if I had a lot of products to change. I need my sample product to have less stock in the POS location than in the warehouse location. Now I can test the changes to settings are working for me. By entering a sale shipment for product "0002P" from workstation 7. I am doing several checks: If I don't want the warehouse to pick from the POS locations. I set the "POS-01" location's supply type to "Quarantine". Then press the pick button again to check this warehouse sale shipment will no longer pick from the location in the pos zone "POS-01".Overview

Procedure

Worked examples

Example for a workstation setup with a default zone being used to enter sale shipments as point of sale transactions

Manage space

Manage content

Integrations