Overview

You can track toners on individual machines.

Ensure the status of the Machine is set to 'Active'.

If you have a part on the machine meter, and the part has no start or end dates and the part is not ticked as 'Is Supply', the task will not generate a service or sales order.

If you have a part on the machine meter, and the part has no start date and is flagged as is supply, the task will not generate a service or sales order

If you have a part on the machine meter parts tab, and there is a start date, no end date, flagged as is supply, the task will generate a service or sales order.

Procedure to set up manual toner supply supported by toner tracking:

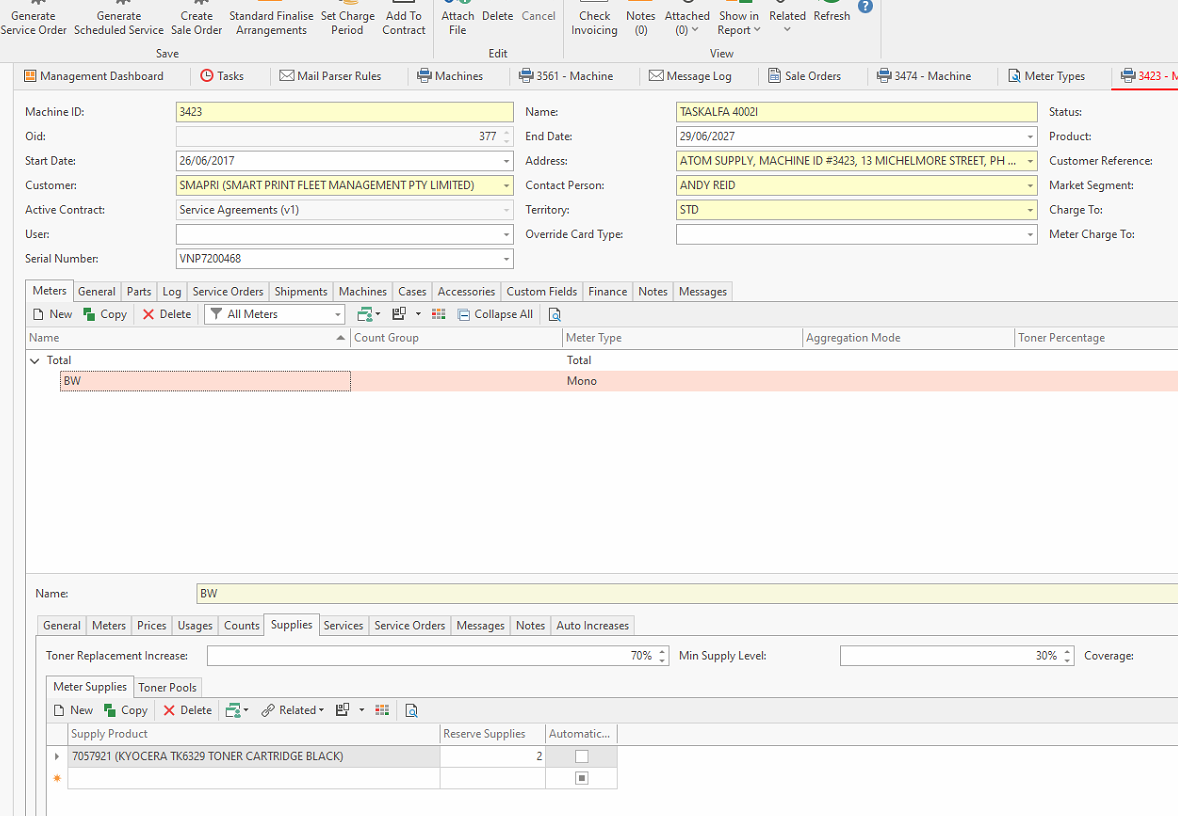

Find the machine, and on each meter set up a value in the field of 'toner replacement percentage increase' on each machine meter eg 75%.

'toner replacement percentage increase' field is the percentage at which the toner level needs to increase to trigger a new toner replacementEg when you insert a new toner and the toner reads that are imported increase dramatically, that is increased by 75%, the system knows that the toner has been replaced.

Adding the Parts to the machine that stands for the model:If you already have the toner parts on the product that stands for the model of the machine, it is easier to add the part on the Machine Meter Supplies tab on the machine itself.

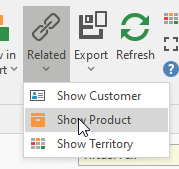

If you don't have the parts stored on the product that stands for the model then follow the steps below to add the parts:From the machine, click on Related in the top ribbon and select Product

- You are taken to the product that stands for the model of that machine

- Click on the tab General>Parts

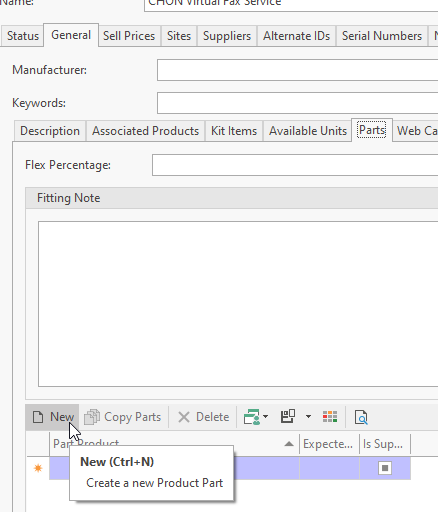

Click on the New action button

- Here you will add the part product id for each of the toner parts and any other parts that belong to that machine.

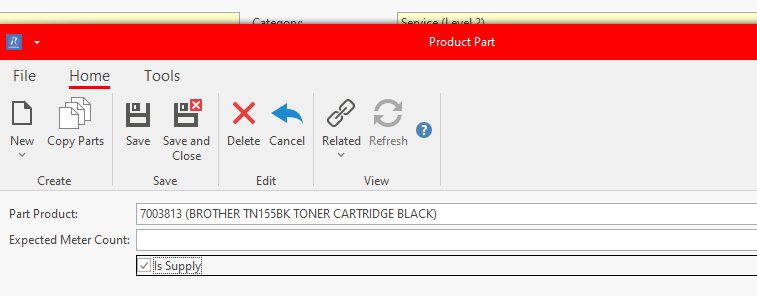

- A product parts window will appear

If the part is a toner, tick the 'Is Supply' check box on that part

- Click on Save and Close

- Repeat the steps to add all of the parts that belong to that machine.

- Click on Save on the product

- Once you have added the parts to the product model, navigate back to the machine

- You need to add the parts to each meter

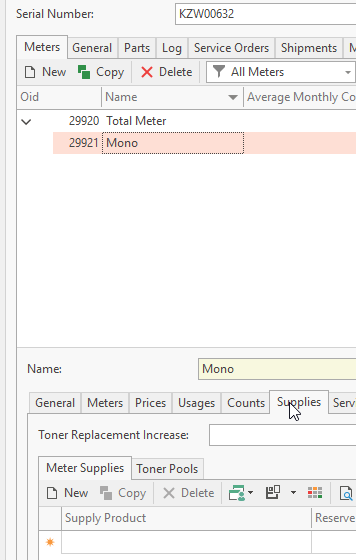

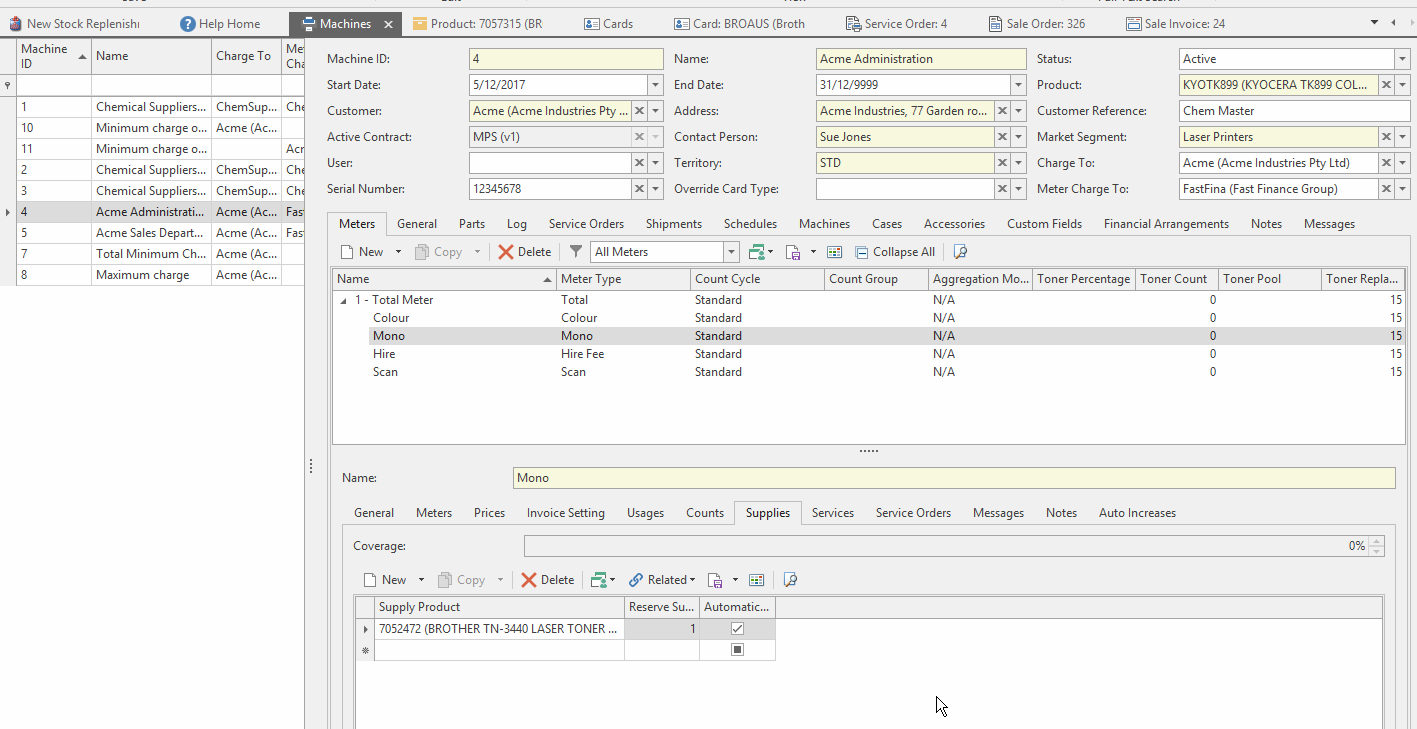

On the machine, click on the Meters tab>Highlight the Meter>Click on Supplies tab.

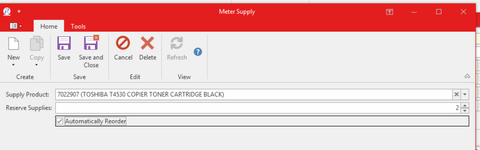

Click on the New action button on the supplies tab

Insert each part product id or click on Search (if you have set up the parts on the product model the parts will appear in the list if you haven't then searched for the part and add it)

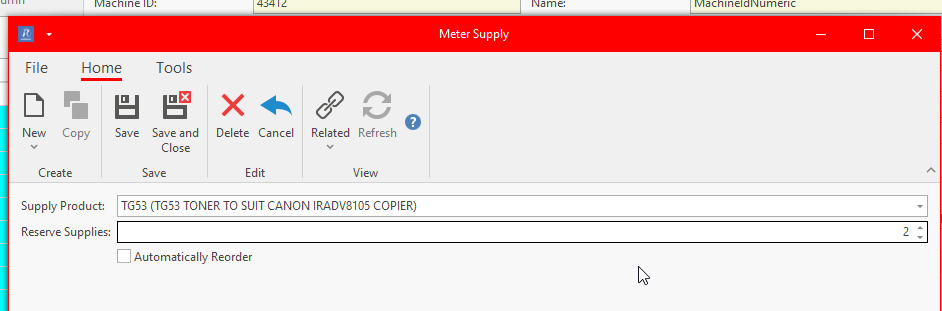

Insert the number of stock required in reserved supplied.

Set the Reserve supplies to a Min of 1 at least or however many spare toner parts for this meter are to be available at the site before a replacement toner is triggered to order. That means that the 1 toner in the printer is not part of the reserve stock quantity.Leave 'automatically reorder' check box OFF.

If this is turned ON, the order is generated via the Task. The task is called 'Generate Recurring Transactions'. This task runs if enabled and based upon the value in the Schedule field.By adding the meter part to the meter supplies, the system will update the field of 'Meter' onto the Machine Parts Tab

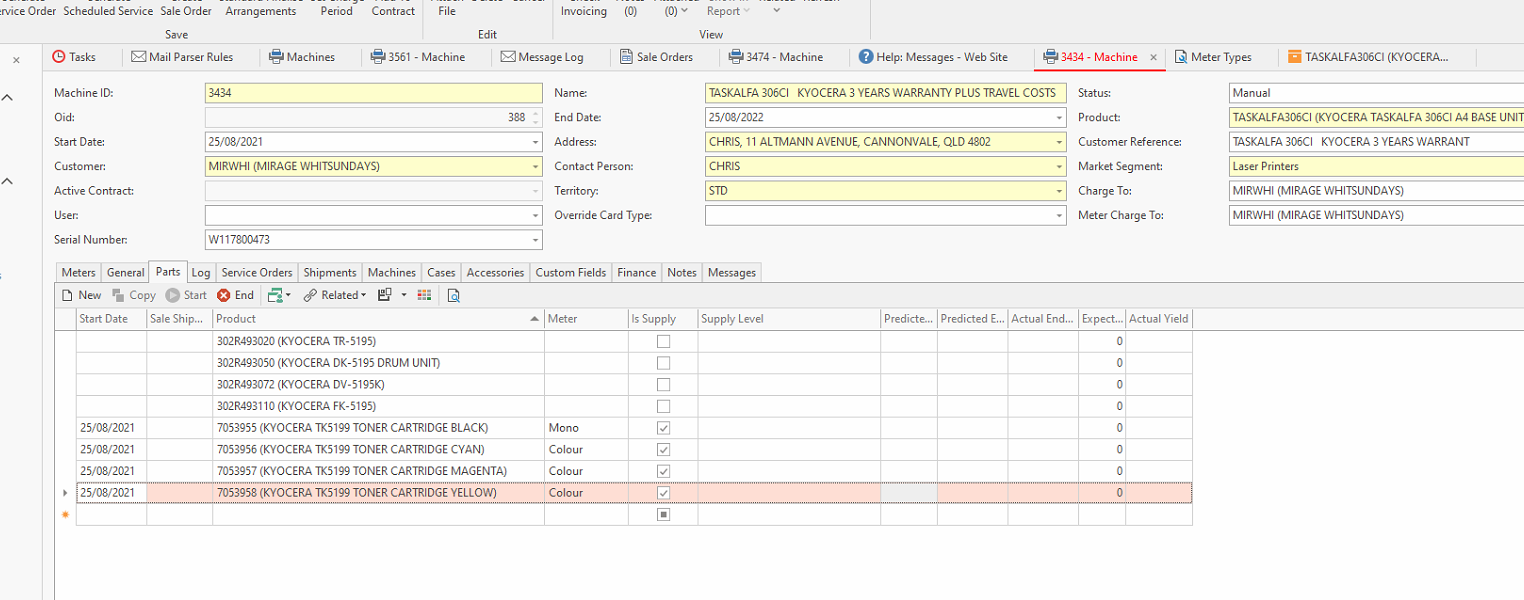

To get toner tracking going the first time around you need to manually set the start date on the first toner/s on each of the machine meters on the parts tab within Machines.

Navigate to the machine

Click on the Parts Tab

The Parts will display and the Is supply is tickeD

Highlight each individual part and click on Start

Manual toner tracking and generating sales/service orders manually for the supply of reserve toners for a machine meter part manually.Insert a sales order or service order and ensure to assign the machine id to the order.

Alternatively, if you are in Machines, highlight the machine in question and click on 'Create Sales Order' or 'Generate Service Order'

Sell a part to this machine (that is product part that is on the meter supplies) for more than a quantity of 1.

Ship and finalise the Shipment or Complete the sales order/service order and generate an Invoice

See my screenshot below for an example. Can be a sales order or service order with a part against a machine-id. Not until the order is shipped and the shipment finalised will the part appear on the machine parts tab for the toner.The part supplied on this shipment is then linked to the Machine-id. You can see this part by going back to the machine and clicking on the Tab Parts

The start date on this Machine Part is set to the date of the sale or service shipment once finalised.

You can manually change and assign the right meter to the Machine Part if you wish to track it manually. Double click on the Machine Product Part and select the right meter and click on Save & Close then Save on the Machine part (see screenshot)The toner reading will come in via either Print Audit and FM Audit or email. The level percentage left on the toner will be read into the Machine Part Supply level field.

- To manually test this, on one of the toners on the machine part that has a start date, insert a supply level of 99% and click on Save.

- Then change the supply type to be 10% and click on Save.

- Then change the supply type again to be 99% (triggering that a new toner has been installed into this machine), the system will end this part and start the next part.

Automated toner tracking with an automatic shipment of toners when required using supply meter product parts

- Find a machine, highlight the meter and set up a value in the field of 'toner replacement percentage increase' on each machine meter eg 75%

Note: The toner on our data field can vary by small percentages from day to day. So as to not trigger a toner replacement due to small variances in the supply level which may be measuring errors, we only recognise the change if the percentage increasing by a substantial amount. We normally set this value to be around 15% into the field called 'toner replacement increase'. - Min Supply level - 25%

- Set up the machine parts for each of the machine meters.

See notes above. - Add the parts to the meter>Supplies

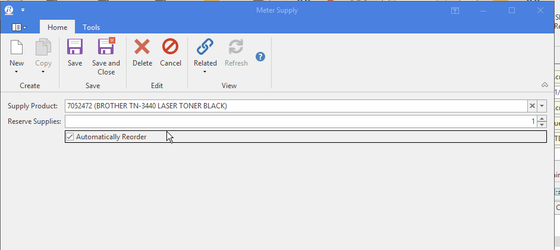

Click on New

Select or Insert each part product id

Insert the number of stock required in reserved supplied

Turn 'automatically reorder' check box ON

Click on Save on the machineIf the part already exists on the Machine part, the part will be updated to have the correct meter type if the part only has a start date and no actual end date and no supply level history and this part will then be flagged as 'Is Supply'.

If the part already exists on the machine part, the part will be added to the list, if the supply level reading has been tracked and new toner is ready for use. The actual end date will be populated as the date of the shipment.

If the part doesn't exist on the Machine part, when the task runs, the system will create a sales order for this part. When the order is shipped the part is linked to the Machine and you can see this on the Tab =Parts, with a blank start date, the field 'is supply' is true and an associated shipment number. See notes above.

When the task is activated to run, the system will create a sales order for this machine-id for the meter supply parts and reserved quantities specified on that machine meter.

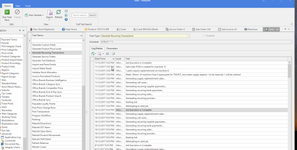

The task is in Administration>Advanced>Tasks>Generate Recurring Transactions>Run Task Now

If you go to the task, you can see in the Text column a result if a sales order was created and for what machine.

Not until the shipment is finalised will the meter supply parts link to the machine parts. Go to the sales order generated by the task and check and finalise it or complete it if you wish to charge it out.

Go back to the Machine>Parts and check the two products.

The toner reading will come in via either Print Audit and FM Audit or email or even manual changing.

The level percentage left on the toner will be read into the Machine Part Supply level field

The rule = all machines /meters that have a machine part with a start date and/or end date will be ignored by the pool and not considered a spare part and will be ordered once the task runs

The toner levels will gradually decrease and then the level will increase by at least 15% or a larger number. That means the toner has been replaced.

When the toner is replaced an end date will be set to the current meter part and a start date will populate onto the next part if there is one reserved.The task is set to run nightly when the reserved stock is filled a sales order will be generated again.

Worked Example

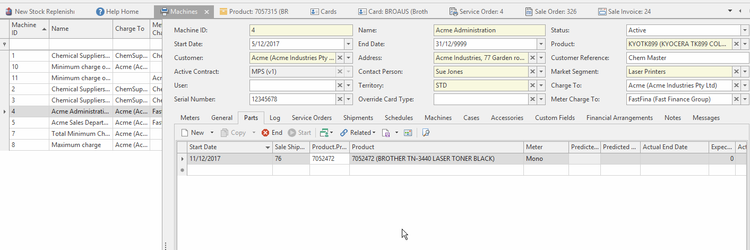

Machine 4 has no machine parts. But when a sale order is posted against the machine, the toner shows as a part of the machine

While the toner shipment causes a part to show on the machine, the part is not linked to any meter. To make parts link to a meter, you have to set up a meter supply on the meter.

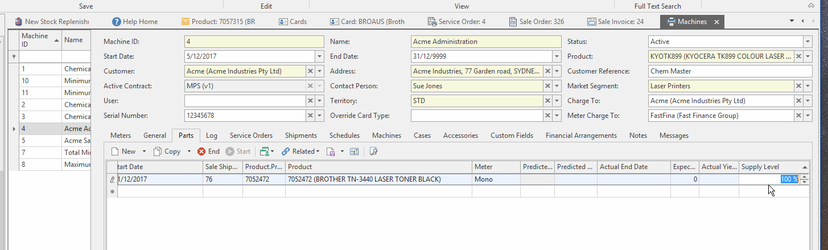

We want to automate the supply of toners for this machine. So we set up a meter supplier for toner "7052472" on the monometer for machine 4. I have also turned on toner tracking by setting the reserve supplies to 1 and turned on automatically reorder to start automatic replenishment as part of toner tracking.

Now that a meter supply is set up, the toner "7052472" supplied to machine 4 on 11/12/2017 is associated with the mono meter.

The start date is set as the day the toner was received, but the end date is still empty. As the Toner has not yet been fully used.

Now you can go to the parts on the machine, given the part is now linked to the mono meter.

Set the toner level to 100% on the part.

When I run the task "Generate Recurring Transactions", the task notices we need to have one reserve toner for machine 4, but the one toner we have is already in the machine. So the system orders one new toner for the machine. You can see why by looking at the log entries on the task

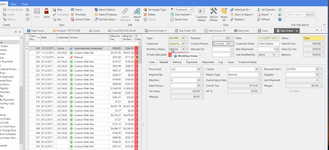

Notice how the automatically generated sale order has a source of "Automatically Generated" and the workflow status of the new order (as of 2018) will show as "OnHold", so that you have to release the order like a web order before it will be picked up by automatic warehousing.

The part is added to the machine part