- From the Navigation panel, click on Inventory, then click on Stock Replenishment Runs

- Click on New button to create a new stock replenishment run

- Click on Extract Products button

- Extract Products windows opens up

Expand You can either select from the existing list in the drop down for Stock Replenishment Run Set or create a new set by clicking on the drop down on Stock Replenishment Run Set and click on button New

Expand - To add a new Stock Replenishment Run Set

- click on that New button

Stock Replenishment Run Set window opens

Expand - Give it a name (something that tells you what this run set is going to do)

- On the From Location Filter tab, use the filter to add in details of where the stock is to be pulled from. i.e. from the warehouse

Expand - On the To Location Filter tab, use the filter to add in details of where the stock is to be moved to i.e. shop

Expand - Click on button Save and Close

From the pop-up window select the Start and End locations for the replenishing extract process

Expand title Show me or in the ongoing example case...

- Click on button OK

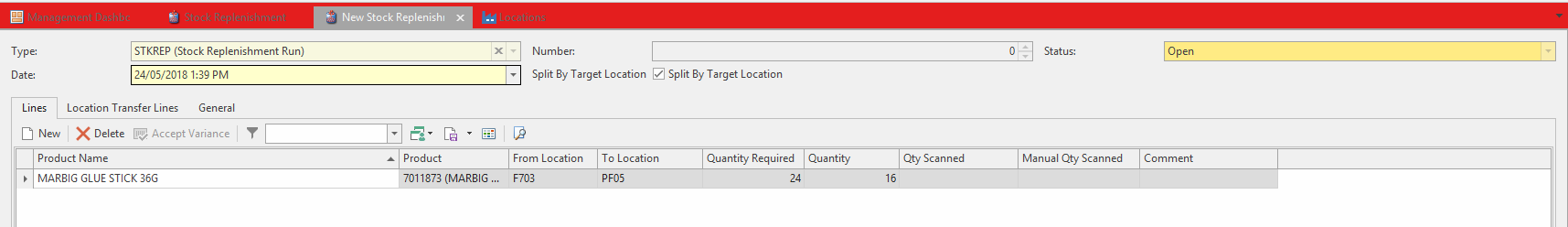

- The New Stock Replenishment window opens showing what stock is available based on the From Location Filter tab above with quantities allowing you to scan or manually add quantities into the the Manual Qty Scanned column to say which ones are going to the location/zone you placed in the To Location Filter tab on the window above.

Update the Quantity to the required level for each of the product lines if required e.g.,Quantity is default to Quantity Required

- Update the To Location if required to be where you want the stock to go.

Expand title Show me Using Using the truck example above

Or using the zone example above

Note If the product QOH is less than the product Minimum Replenishment Quantity then Quantity Required = Maximum Replenishment Quantity - QOH

- Click on button Save

Click on button Generate Transfer to create Stock Location Transfer transactions for this run and Post the run

Expand title Show me - Use Stock Location Transfer function to list and select the transfer transactions generated from the step above to action

Page Comparison

Manage space

Manage content

Integrations