...

From the Navigational panel, click on Administration, click on Sites then select Settings tab to view the Auto-warehousing settings. (Sites > Settings > Auto-Warehousing)

Expand title Show me - As seen in the image above there are a few fields and flag which required input from the operator such as:

- exclude web orders from auto-warehousing run until its workflow status is changed to Ready by the user

- exclude web order if any product-id is equal SPECIAL i.e., product order from the web site does not exist in the inventory; until it is changed to a valid product-id

exclude sale orders with OnHold Workflow Status

Expand title Show me ([Workflow Status] Is Null Or [Workflow Status.Name] <> 'OnHold') And ([Transaction Type.Code] <> 'SALWEB' Or [Transaction Type.Code] = 'SALWEB' And [Workflow Status.Name] = 'Ready' And [Sale Order Lines][[Product.Product ID] = 'SPECIAL'].Count() = 0)

- Generate Shipment flag must be on/checked.

- Minimum Allocation % is used to work out if any orders might be ready to release. The system checks the percentage fully allocated for each order. If any order has a percentage fully allocated that is greater than or equal to the site specified Minimum Allocation % then that sale order will be considered for generation of a sale shipment and picking slip.

It is critical that you are aware that automatic warehousing uses Percent Fully Allocated on the order. This is totally different to the simple Percent Allocated figure on the order. If you look at percent allocated and try to understand what automatic warehousing is doing you will get confused. Stick to Percent Fully Allocated on the sale order. Refer to Understanding Percent Fully Allocated and Linkage to the Auto-Warehouse Function for more details. - Maximum Shipments Outstanding is used in deciding if the warehouse has the capacity for any more shipments. Automatic warehousing will only cause a new sale shipment to print if the warehouse team have time to work on the picking slip. It does this by using the maximum shipment outstanding as a measure of the warehouses total capacity. If the number of sale shipments being picked in the warehouse is greater than or equal to the maximum sale shipments outstanding the warehouse has no spare capacity. Automatic warehousing will stop releasing picking slips. It will wait until the number of sale shipments being picked in the warehouse falls below the maximum shipments allowed to be outstanding in the warehouse at one time. If for example the maximum shipments outstanding is 50. If there are 51 sale shipments in the warehouse, automatic warehousing will wait. Once the number of sale shipment fall below 50, automated warehousing will regard the warehouse as having the capacity to handle more sale shipments. It will then check and see if there are any orders that might be ready to be considered for picking.

Minimum Age can be expressed as minutes or hours The system reads the time at which the sales order was last saved. It then adds the minimum age to the last saved time and checks if the last saved time plus the minimum age is less than the current time. If so the sales order is considered for picking. If not automated warehousing waits until the time span since the sales order was last saved exceeds the minimum age. It then considers the sales order for picking.

Note This is expressed in 60 minutes so to calculate the Minimum Age value use the following formula Minimum Age = Order age in minutes / 60

e.g., For order age is 6 minutes it is calculated as follows

Minimum Age = 6/60 = 0.1

- Mins of Priority for Cut Off : If this is set when the task is considering releasing shipments and where more than one shipment could be released. Give priority to any shipments where the related carriers cut-off time (Administration>Carriers>Cut Off Time) happens within the specified number of minutes.

- Always Release Priority to always release shipments if any lines on the order with supply type of 'Priority' and that line is fully allocated.

- Criteria is optional and used to include or exclude orders from Auto-warehousing run e.g:

- The built-In/programmed criteria are

- Exclude sale quotes from auto-warehouse

- Exclude sale order if there is a Ship After Date and it has not reached

- Include sale order with status Open or InProgress

- Supply Type (see supply types)

- Ensure the printer which is used for Auto warehousing is installed on all workstations and server involved with Auto warehousing and configured to the workstation settings to the Picking Slip layout.

In the Workstations>General Settings, the Execute Printing Queue flag must be on/checked.

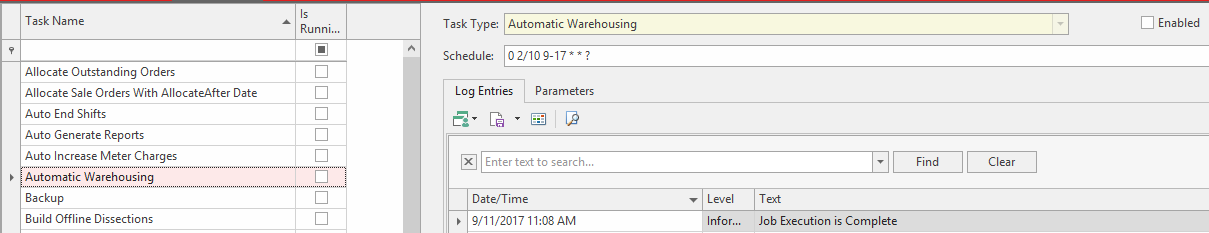

Expand title Show me - In the Administration>Advanced>Tasks section of Readysell, select the Automatic Warehousing task (previously know as Generate Shipments for Allocated Orders), it is required to complete the following step:

- Ensure the task is enabled.

Set the schedule to the required time by the client. E.g. Prints order every five minutes during working hours (0 2/5 7-18 * * ?). This translate that it will run every 5 minutes from 7am to 6pm, 7 days a week.

Expand title Show me *ContactReadysellSupport to change the task schedule e.g. to run from 8am to 4pm Monday-Friday only, the Schedule would be 0 2/5 8-16 ? * MON-FRI

*Restart ReadysellServer service to effect the change

- Once settings are enabled, testing is required by creating a sale and ensure that each stage is completed. The workflow should be as follows:

- Create sale order and save the order.

- Wait the time allocated to the print job and confirm that a picking slip is produced.

- Once that is confirmed, check the order and see if a shipment is created.

...